WPC Cladding

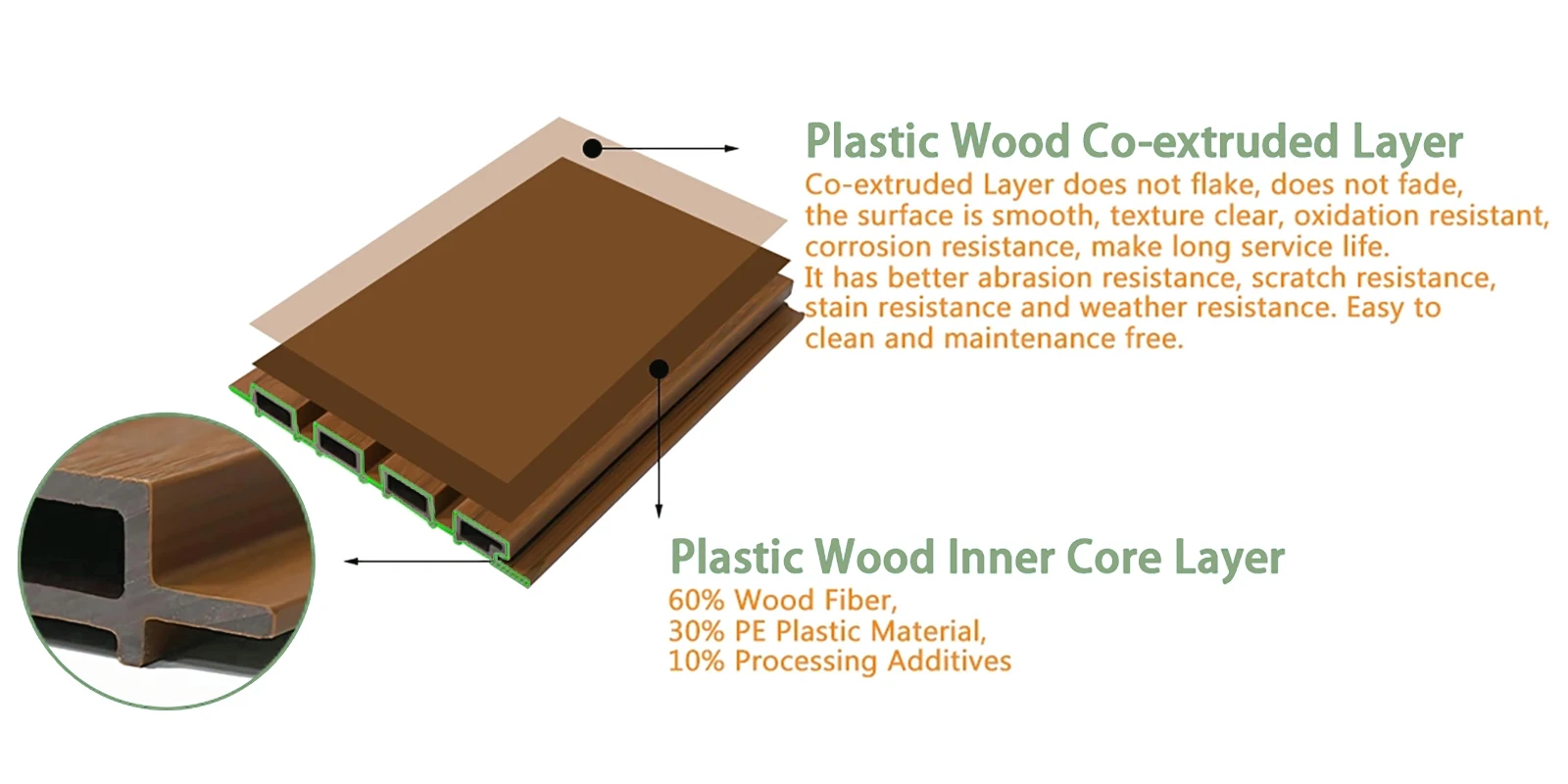

Materials: 60% wood fibers+30% HDPE+10% additives

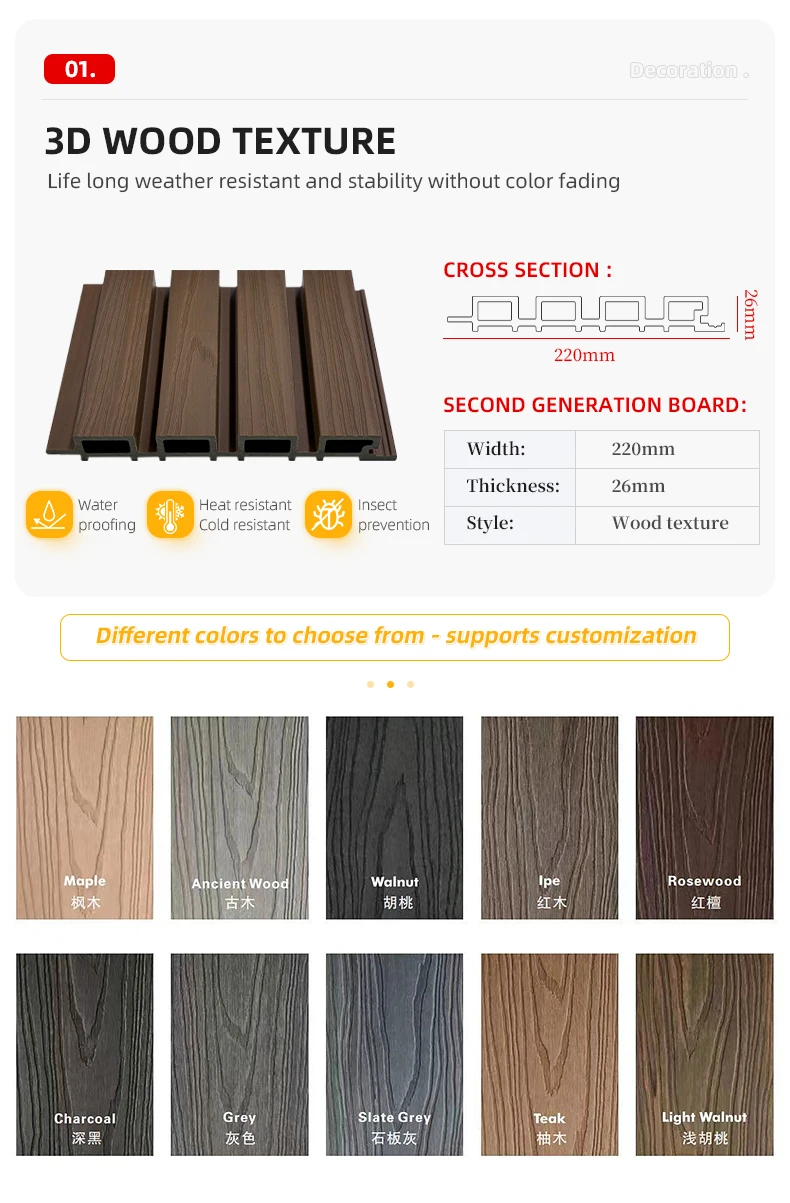

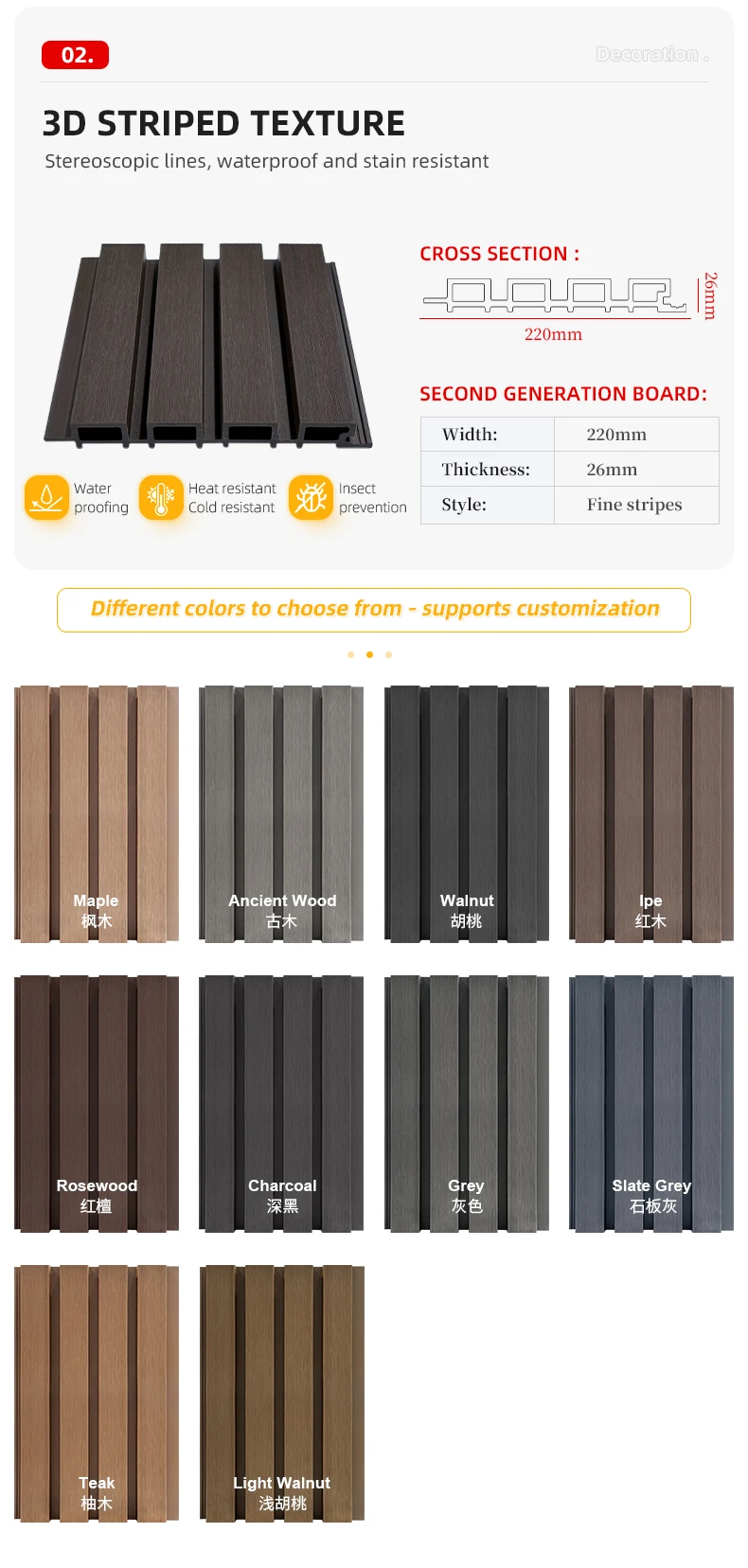

Size: 220x26mm, 219*26mm,150x16mm, 165x20mm, 175x21mm or customized

Surface design : Brushed, Grooved, Striped, Mixed color, Wood grain,Sanded

Colors: Black, Dark Grey, Brown, Oak, Teak, White,Grey, Light Grey or customized

Fire Rating: Class B

Working environment: from -40 to 60 Degrees Celsius

Advantage: 1. easy to install, easy to handle

2. low maintenance

3. waterproof, fire retardant,anti-insect, UV-resistant

4. stable & durable, impact resistant

5. weather resistant, less fading

6. eco-friendly,long lasting

- Specification

- Contact Us

Product Details :

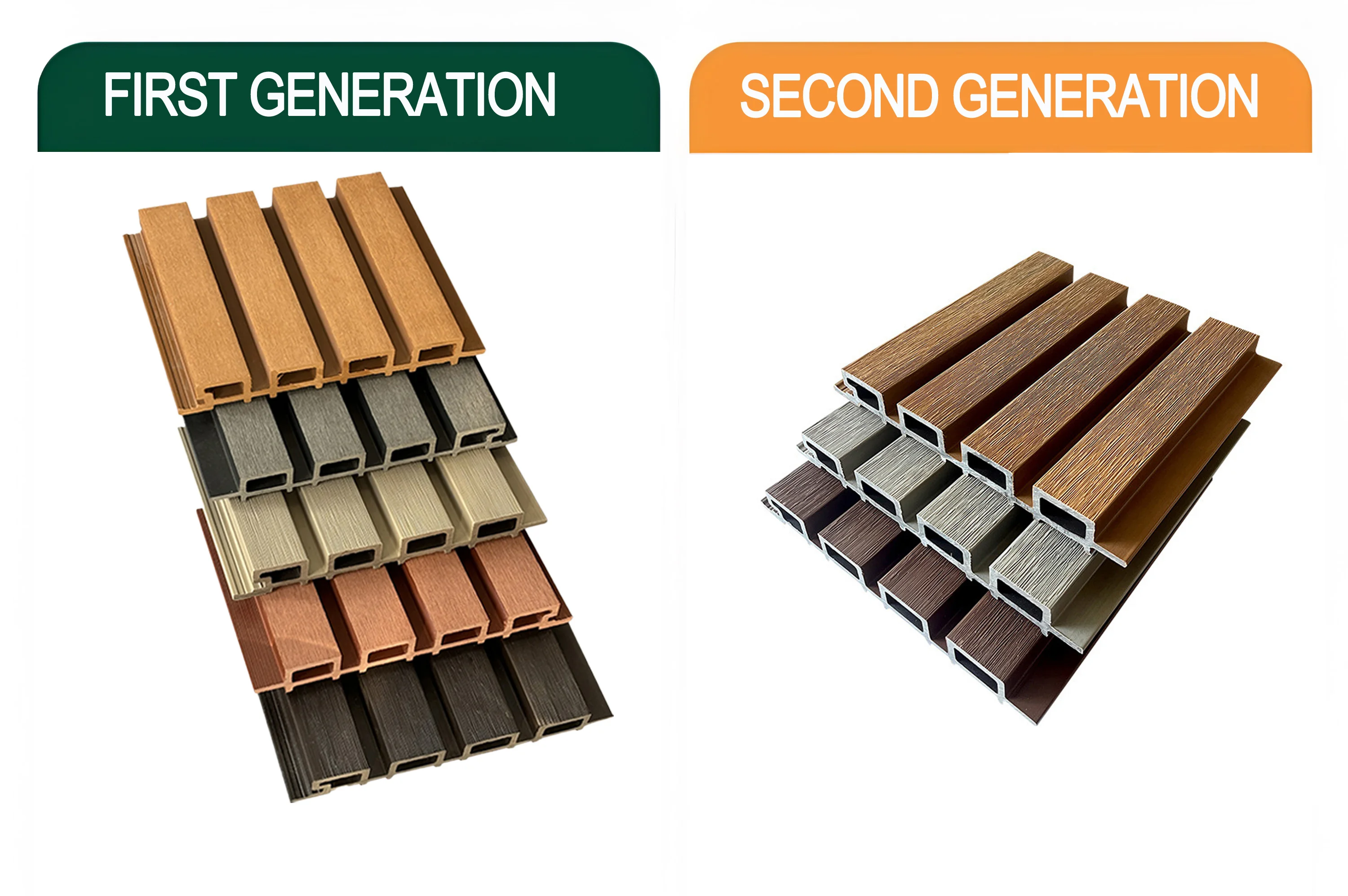

Co-extruded wood-plastic, also known as second-generation wood-plastic composite (WPC), represents an innovative upgrade based on traditional WPC materials. This technology integrates a wood-plastic substrate with a high-toughness plastic protective layer (typically PE or ASA) through one-step heating, molding, and pressing, eliminating the use of adhesives throughout the production process to avoid chemical pollution. The "substrate+protective layer" dual-structure design completely eliminates gaps between layers, enhancing overall product strength and delivering durability and protective performance unattainable by traditional WPC.

Core Technical Features

Size and patterns :

Why Partner with Us?

With 15 years of expertise in wall & floor panels and 200+ global clients—from residential projects in Europe and America to iconic landmarks in Southeast Asia—we deliver competitive pricing and market stability through large-scale production and direct sourcing.

Beyond efficiency, our custom solutions—featuring unique textures, sustainable technology, and modular designs—are tailored to local trends, giving you a decisive market edge. In fact, 70% of long-term partners achieved regional leadership within 2 years of collaborating with us.

We share risks through joint research and inventory planning, helping you navigate industry fluctuations. Our commitment goes beyond transactions: enjoy 3-year partnerships, full after-sales support, and a proven track record of 500+ success stories.

Partner with us—let our expertise drive your growth.

CONTACT US

Related Products

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.